A show level car is a

99 + point or better vehicle. These vehicles are generally not driven

more than a few miles a year and found in a museum or collection. They

may also be found in a climate controlled facility and transported in an

enclosed trailer to Concours and car shows. All components are original

or an exact replacement. Classic Showcase does their utmost to locate

NOS (new old stock) parts for every vehicle. If a specific part is no

longer available in NOS, we source the best aftermarket parts available.

This level of nut and bolt restoration may

be daunting to most companies; however, Classic Showcase’s top

specialists have the experience and expertise to complete these projects

successfully. With our knowledge of the rules and regulations in judged

events, we are able to provide unsurpassed work and craftsmanship with

the proper restorations and reconstruction of our cars.

To begin, you must use the best original car as

possible to achieve the best results. The more originality the car has

the better it will turn out. A lot of pre-planning has to occur before

beginning the project. This requires very precise workmanship through

the whole project and keen attention to detail.

Similar to our other levels of restoration,

we start all our projects with a complete and comprehensive evaluation.

We research the vehicles history and check for any and all documentation

we can find. We carefully look the vehicle over, noting what is

original, what has been altered or what is not working, and what is

missing. We start to assess the overall condition and document it with a

complete set of photographs and notes. After doing various extensive

tests and evaluation inspections on the vehicle, we then start the

disassembly of the vehicle, again taking note of all parts and listing

what will need replacing, restoring, or repairing, also making note of

originality as we proceed.

The interior,

including panels, dash, seats, and carpets as well as the top on the

roadsters are redone with proper high quality materials. Our upholstery

department ensures the usage of proper patterns, design, stitching,

color, texture, and even the hardware. Our craftsman stitch and install

the pieces for a custom look and fit. Sometimes it can take up to three

days to acquire the ideal fit of the top. The best carpets, leathers,

and fabrics are bought for the vehicle and used on the convertible top

and interior. The craftsmanship is critical to the overall look.

A new wiring harness is almost always installed.

The wire loom is restored or replaced using an original style that does

not take anything away from the original aesthetics. The electrical

components, instruments, gauges, knobs, lights, and switches are

re-screened, restored, rebuilt, or replaced.

Next, all the mechanical items on the

vehicle are carefully gone through. The engine is broken down and

evaluated for any damage. The block, head, crank, and cams are then sent

out to the machine shop to be hot tanked, magnafluxed, measured,

balanced, line bored, and blueprinted as needed. Once the engine has

been set to factory standards it returns to us for a final inspection

and reassembly. All the wearable parts are replaced such as pistons,

piston rings, bearings, valve guides, seats, springs, seals, timing

chain, etc...

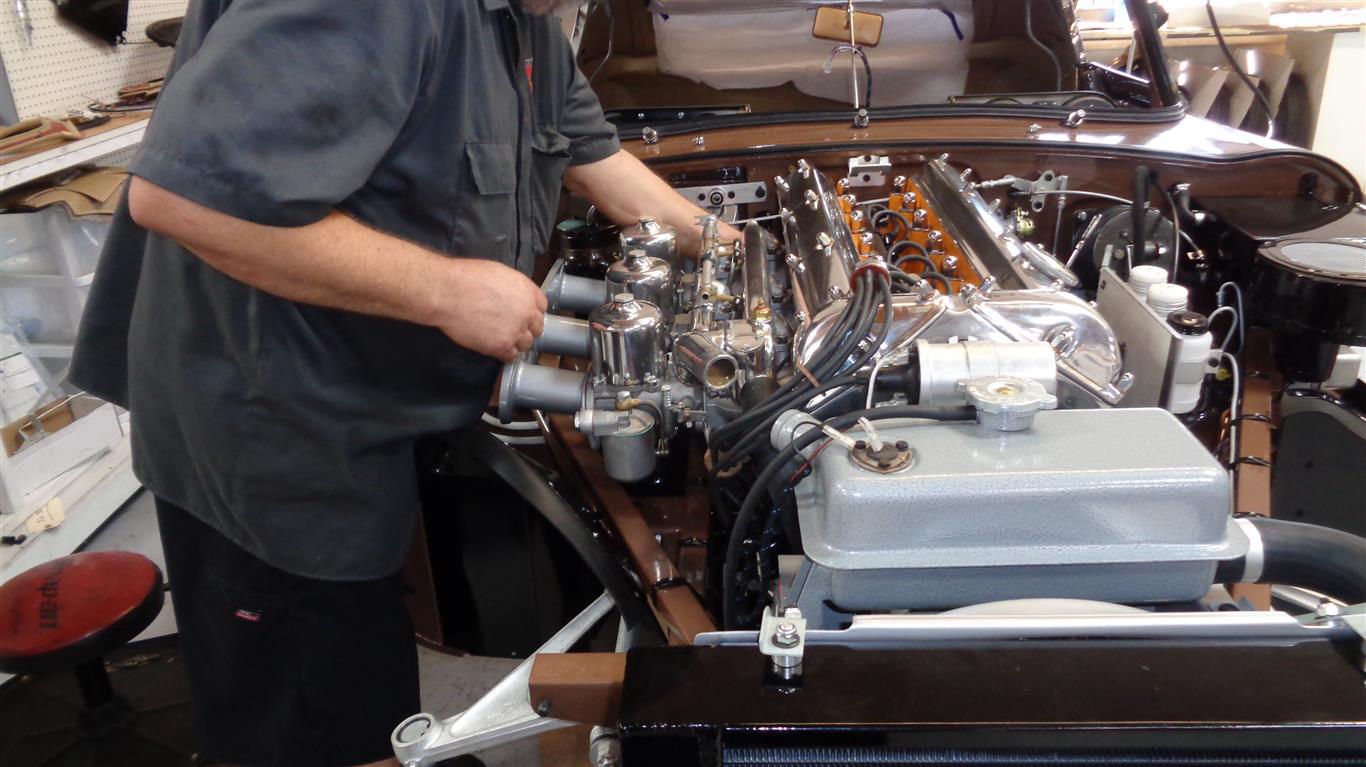

All the components in the engine compartment

are removed and evaluated. The parts are cleaned, restored, or replaced

and painted or re-plated with the proper color or finish if needed. The

following parts are rebuilt or replaced; carburetors, oil pump, water

pump and generator/alternator. The radiator is hot tanked and re-cored

or replaced. All the belts, hoses, filters, fluids, and hardware is

replaced down to the last proper hose clamp. The stone guards and drip

pans are also restored or replaced.

The transmission is rebuilt using new gears,

seals, lay shaft and syncros as needed. The clutch system is rebuilt or

replaced when necessary. The drive shaft is balanced. The under carriage

is rebuilt, including the shocks and suspension parts. Many of the

structural hardware pieces are upgraded from a grade 5 to a grade 8 for

durability. All new bushings, seals, hardware, and components are used.

In most vehicles the frame and suspension parts are media blasted and

powder coated in the proper colors for durability and longevity.

The

braking system is restored from the master cylinder to the rear shoes

or pads. The wheel cylinders are honed, re-sleeved in brass or stainless

steel for a lifetime guarantee and new seals and pistons are installed.

All the brake lines are replaced, along with the shoes, drums, pads,

and rotors. The rear end gears are checked, calibrated, and rebuilt,

replacing parts as needed. The gas tank is removed, flushed, hot tanked,

repaired if needed, then epoxy sealed or replaced and refinished to

high standards. The fuel pump is replaced or rebuilt as well as the fuel

lines. A new exhaust system is fitted to the vehicle. The battery is

replaced with the correct size. All five wheels are replaced or restored

and trued before we mount the proper vintage style tires on them.

After

the vehicle has been reassembled, our craftsmen and technicians do a

complete check to make sure everything is in excellent working order. We

complete a pre-service test drive, adjust the valves, re-torque the

head, check the tolerances of the engine, and re-torque the nuts and

bolts throughout the vehicle. Creating a Show car can take almost twice

as much labor as a Driver level due to the attention needed to every

detail.

Often, we take the vehicles out to various

shows to win awards before offering them for sale. This helps ensure our

customers receive that Pedigree show winner! Right before a vehicle is

ready for its new home, we complete a final detail and show its new

owners the proper way to drive, care, and maintain for their new

classic.